COMPETENCES

Our success as one of the world’s leading OEM manufacturers of components for minimally invasive medicine is based on the special competences and unique expertise we have acquired over decades. In addition to a high-quality basic range, we provide the entire process from initial consultation to the declaration of conformity and the approval of products and components individually tailored to the respective requirements.

CONSULTING

Do you have a very precise idea of your guide wire or nitinol basket that is tailored individually to your requirements? Do you wish to receive any suggestions from an EPflex expert? In any case, we will advise you.

DEVELOPMENT

We provide the complete process from the initial planning of the project up to the declaration of conformity.

FEASIBILITY

- Project planning

- Requirements specification and functional specification

- Researching standards

- Risk management

- Profitability

PROTOTYPES

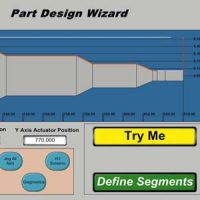

- Product design

- Packaging

- Sterilisation

- Prototyping

- Pilot production

APPROVAL

- CE certified according to 93/42 EEC

POST MARKET

- Market surveillance

PRODUCTION EXPERTISE

Specially trained personnel, state-of-the-art production facilities and ISO class 8 clean rooms: We produce high-tech instruments at the highest quality level.

In-house fixture and special machine construction

Raw material stock

Wide choice of coil material: Coated, Uncoated, Nitinol, Stainless Steel

Cutting to length and deburring

Deburring of cut edges with control under camera system – over 60,000 wire cuttings per day!

Burr free cutting

Electrochemical “Everite” cutting saw

Vibratory grinding (trowalizing)

Special process for surface treatment: deburring, rounding, polishing, matting

Sandblasting

Roughening and deburring of wire sections in 3 fully automatic sandblasting machines

Flat pressing

Increase of pliability without loss of tensile strength

Grinding

Our core competence – 46 grinding machines with automated loaders and 6 CNC grinding machines for special grinding contours

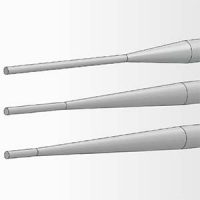

Centerless grinding

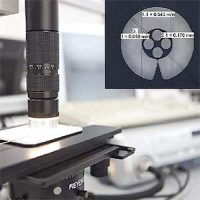

For cylindrical or conical contours up to Ø min. 0.09 mm

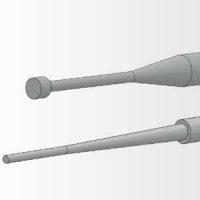

Plunge grinding

Grinding of special profiles up to Ø min. 0.1 mm

CNC grinding

Grinding up to Ø min. 0.05 mm e.g. for PTCA wires

Fully automatic testing

Checking diameter and necking 100%

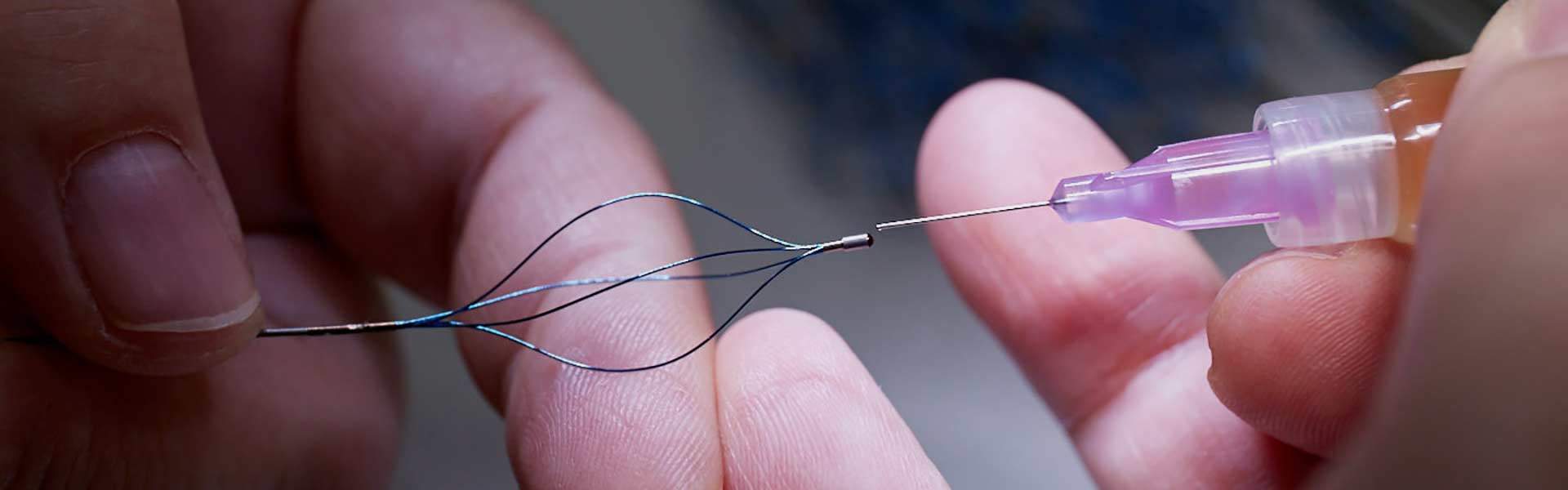

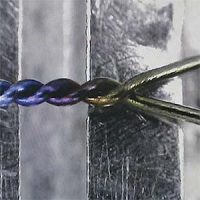

Forming nitinol wires

Twisting of wire components, thermal forming and special shapes

Stainless steel wire forming

Manual or semi-automatic forming of wire ends, e.g. eyelets

Form J tip

Manual or semi-automatic application of various tip shapes

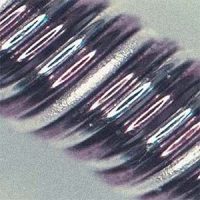

Springs wrap over stylet

Sample production of special springs – the illustration shows a spring made of three different materials

Elongation of springs

Spring elongation in defined range

Laser welding

Welding of metallic components, e.g. baskets or rounding of stilettos – over 20 laser workstations

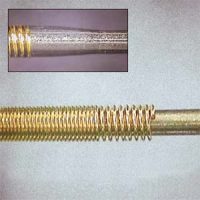

Plasma welding

Creation of a semicircular welded joint between core and spring – 19 plasma welding workstations available

Gluing

Creation of an gluing bond between spring and core wire – 23 Semi-automatic bonding systems

Gluing proximal

Attachment of a transition between spring and core on particularly thin or sensitive components

Marking

Electrochemical marking of stainless steel surfaces (oxidation process)

Laser marking

Applying markings with the use of a laser

Laboratory

Organic and physical chemistry laboratory

Passivating

Improvement of the corrosion resistance through chemical modification of the surfaces

Dip coating

Application of hydrophilic plastic coatings

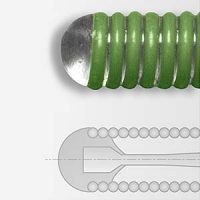

Shrinking and rounding

PTFE hoses are shrunk on to guide wires and rounded off

Pebax tips

Attaching Pebax tips to pre-ground core wires

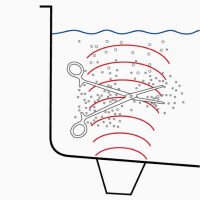

Cleaning

Parts are cleaned using appropriate methods (e.g. ultrasound) and selected cleaning cycles (cleaning, flushing, drying, while taking temperature and time into the account)

In-process control

Fully automatic tensile test 100% – Optical measuring method up to 1000x magnification

Dispenser

Clipped and welded variants

Sealing

Packaging medical products by sealing them in sterile pouches

PACKAGING AND STERILISATION

We guarantee safe and sterile packaging for all EPflex products and we will respond exactly to your wishes and ideas.

REGULATORY AFFAIRS

We support you in the approval of your medical products developed in cooperation with us and you can buy from us products manufactured and ready-certified according to your requirements.

Quality management

Our quality management system complies with the requirements of the ISO 13485 standard and the regulation 2017/745 MDR.

We are a member of the

Guidelines

Regarding our guidewires (Class IIa and Class III) and stone retrieval devices (Class Is), our quality assurance system complies with the requirements of the directive 93/42/EEC Annex II without section 4

Our class III guidewires are designed in accordance with the essential requirements of directive 93/42/EEC, annex II, section 4

Other requirements

We were also able to prove in corresponding audits that we fulfil the following requirements:

- 21 CFR 820 (USA)

- RDC No. 16 (Brazilian GMP)

- MHLW Ministerial Ordinance 169 (Japan)

- Korea GMP

- Taiwan GMP

Your contact person

Dr. Johannes Uihlein

Managing Director

T +49 7123 9784-0